Radiographic Testing

Add your title here

This is the text area for this paragraph. To change it, simply click and start typing. Once you've added your content, you can customize its design by using different colors, fonts, font sizes and bullets. Just highlight the words you want to design and choose from the various options in the text editing bar.

This is the text area for this paragraph. To change it, simply click and start typing. After adding your content, you can customize it.

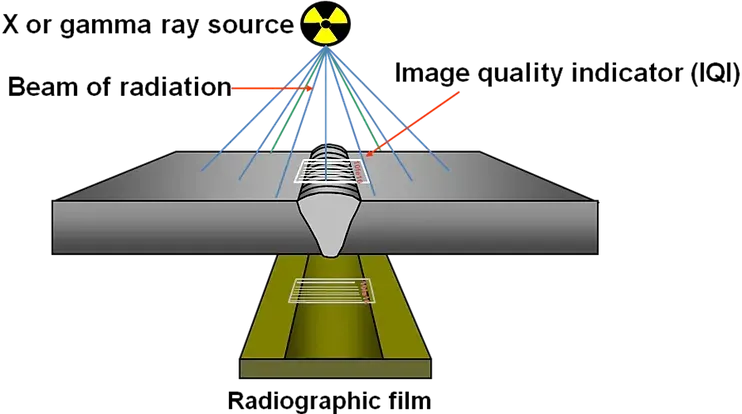

Highly penetrating radiation is used to detect internal discontinuities in a wide range of materials. As a nondestructive examination technique, x-rays or gamma rays are used to examine the internal structure to ensure all project specifications are met. Radiographic testing works by exposing the subject of the test to specific types of radiation. The radiation or x-rays will pass through the object, and then the detection equipment will record the results.

Dark areas indicate more radiation has passed through, this commonly indicates a void, defect, or other flaws in the test subject. Since the rays used do not damage the object, it is safe to use after testing. Due to its ability to detect flaws in internal structure Radiographic testing is a very common non-destructive test.

Entec Consultants offers a full suite of inspection, nondestructive testing, and QA/QC services.

All services offered can be performed in-house or on-site.

Specialized Services

- Video & Fiber optic video boroscope inspection

- AWS-CWI inspectors

- ASNT level III services

- Welder qualifications, Procedure qualifications

- Welder training

- Process safety management & vessel integrity

- Digital cameras

- Autocad & excel reporting

Items Commonly Tested

- Kiln sections

- Structural steel

- Turbines

- Boilers

- Digester vessels

- Pipe welds

- Heat exchanger tubes

- Storage tanks

- Paper machines

- Deaerator tanks